Three particularly fascinating areas of research at the Cleantech Hub include:

You may have heard of carbon capture, which physically captures carbon from the air. Carbon recovery is different.

“The kind of carbon recovery we’re focused on at the Cleantech Hub is taking industrial waste, working with it and converting it into high-value, large-scale advanced products” says Dr. Thomson. “We develop cost-efficient and industrially relevant methods for upscaling processes.”

Used off-the-road (OTR) tires, particularly those from the mining industry, which are gigantic in size and difficult to recycle, are one area of Cleantech Hub’s carbon recovery focus. Because rubber burns, it cannot be melted down to be converted into something new the way some plastics can.

Instead, rubber requires a mechanical process in order to be recycled. Researchers at the Cleantech Hub are applying innovative technologies to produce recycled carbon black from OTR tires; as rubber reinforcements that would give it a second life as shoe soles or car tires, for example.

A third potential application for carbon black that Dr. Thomson says holds promise, is, of all things: batteries.

“With wearable electronics, we’re experimenting with embedding material into clothing that can receive information from the body, like the wearer’s heart rate,” says Dr. Mohammad Arjmand, Canada Research Chair in Advanced Materials and Polymer Engineering and Assistant Professor at UBC Okanagan.

There’s also potential to weave GPS into your running shirt, for example. But this particular technology poses challenges; the washing machine is one of them, everyday wear and tear is another.

“When you wear something, you can imagine that fatigue is a big problem, because you move around constantly. So if the material is not resistant to wear, after a matter of weeks it’s not going to be usable anymore,” says Dr. Arjmand.

“Performance durability is very important.”

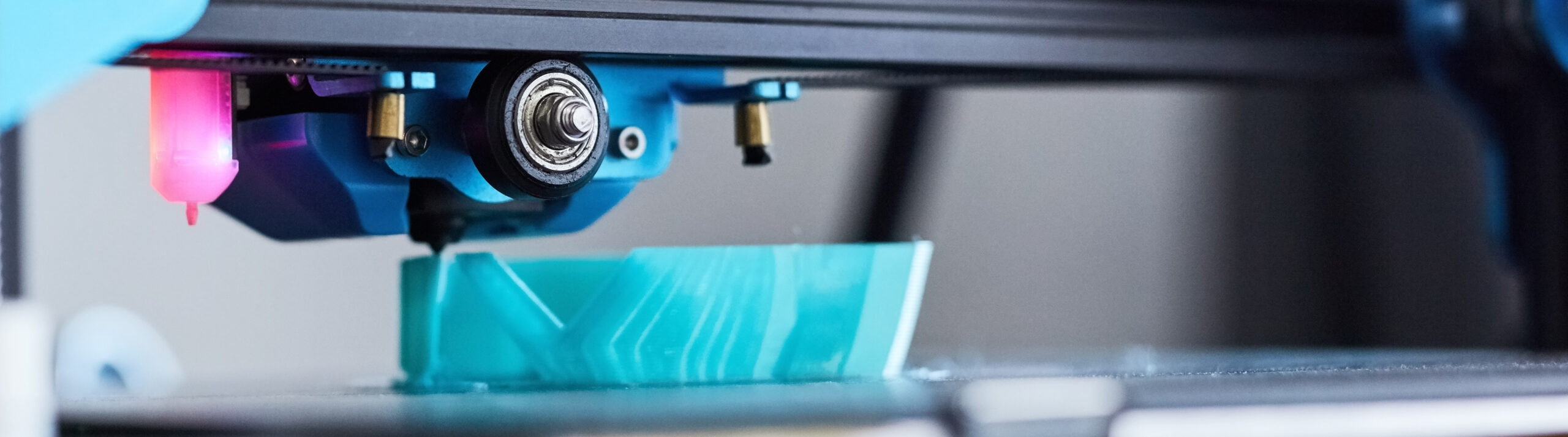

Today, 3D printing offers almost limitless possibility—at home, in a lab, and even at Science World.

“A lot of our exhibits are extremely customized,” says Greta Burley, technical designer at Science World. “Some are one-of-a-kind, others were built 30 years ago and there are no plans for it anymore. So 3D printing allows us to create something entirely customized, like specific enhancements for our axolotl

habitat or interactive elements like our Story Stacker.”

(She also points out there’s a 3D printer Science World visitors can see in action in Tinkering: The WorkSafeBC Gallery.)

There is an emerging technology—and this, Dr. Arjmand says, is so advanced it is nowhere near ready for an everyday application—called 4D printing.

In this type of printing, time is the fourth dimension, meaning the thing that’s been printed will change over time when exposed to external stimuli such as heat.

“We could make the materials responsive to a change in the pH of the environment, or UV light or heat, so it would start to react to that stimuli,” Dr. Arjmand says. “We can make it smart and give it desired functionality for different applications.”

Curious for more science behind the technology of climate change?

Explore solutions for regenerating our planet on Change Reaction.