Sometimes the biggest innovations are made possible by the tiniest discoveries, like those of a micro—or even nano—scale.

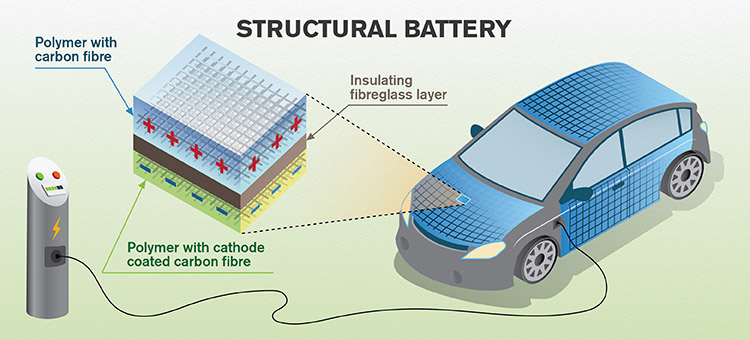

Engineers love carbon fibres at this scale because they’re lightweight and super strong, but up until now, they’ve been incredibly expensive, accessible only to big-budget industries like aerospace, aviation, and professional athletics, where a $1,000 hockey stick or $5,000 bike is standard fare.

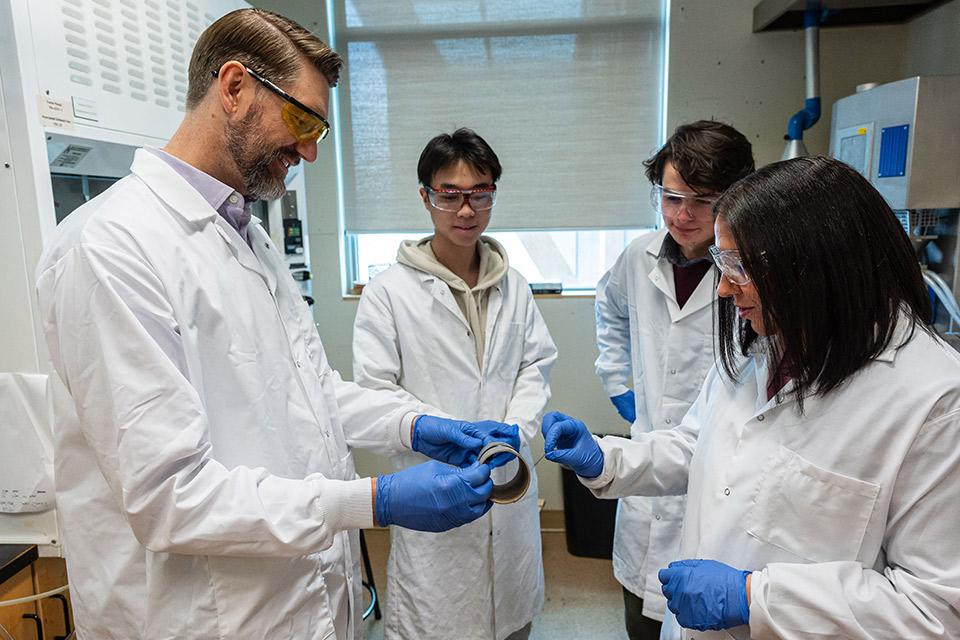

Dr. Yasmine Abdin, materials engineering assistant professor at the University of British Columbia, and her team have discovered a way to make carbon fibres out of a by-product of the oil and gas industry called asphaltenes AsphaltenesHigh-molecular-weight molecules containing carbon, hydrogen, nitrogen, oxygen, and sulfur, often considered the heaviest and most polar components of crude oil. .

This has two distinct benefits: it finds a use for a by-product that can be toxic when it’s burned. And two, it makes carbon fibres far less expensive; cutting the cost almost in half.

“Now, not only aerospace can afford to use carbon fibres,” says Dr. Abdin, “But sectors like automotive can now afford them too and make vehicles lighter in the process.”